FAQ

Frequently Asked Questions

Our vision is a sustainable and circular world. A world where we reuse what we have in use, where we import less and look for local solutions and raw materials. In everything we do, we consider the environmental impact of our products and our production process.

Sustainability

Climate Signs uses only recycled or biobased raw materials. In this way we extend the life cycle of existing raw materials, significantly reduceCO2 emissions and upgrade existing traffic solutions. Climate Signs stands for sustainable product development, achieving an energy-neutral environment and creating support for circular thinking and doing.

To keep tomorrow’s world affordable, livable and sustainable, we will transition from a linear ‘take-make-dispose’ economy to a circular 3R approach ‘reduce-re-use-recycle’ economy. Through the innovative honeycomb design, we minimize raw material use (reduce), maximize reuse (re-use) through a proprietary recycle return system, and reuse (recycle) raw materials at the highest possible quality.

The Climate Signs resources are:

- Waterproof

- Fireproof

- Antibacterial

- Non-toxic

- Thermally stable

- Environmentally friendly

- Resistant to chemicals

- UV-Stable

- Recycled

- Antistatic

- Sustainable

Climate Signs’ road signs all fall under the VNVF level gold of the VNVF Ultimate Signing durability rating

The Climate Signs traffic signs have a long service life, whereby the quality and technical longevity remain guaranteed. The sign is resistant to extreme weather conditions (between -40 and +80 °C) partly due to its innovative design. The material is rigid, tough, possesses high impact resistance, dimensional stability and non-toxic properties. The signs are supplied in accordance with the VNVF Ultimate Signing 20 year standard. This includes an expiring 20-year warranty

- We produce our traffic signs and other products from high-quality residues from the Post Consumer Recycling and Post Industrial Recycling waste streams. By not using new petroleum (fossil) raw materials, we produce 100% sustainable products. Products from Climate Signs:

- Last longer than innovative alternatives

- Saving on primary resources, through 100% use of recycled materials;

- Ensure that high-quality raw materials are safeguarded for future generations. Our products are 100% recycled.

- Life cycle assessment (LCA) is a calculation method to universally determine the environmental impact of a product. Climate Signs is the only traffic sign supplier in the Netherlands to have had a Category 1 LCA study performed. The results are available for free download on the site of the National Environmental Database (NMD), or on the Climate Signs website at documents.

Statement category LCA studies:

Category 1 LCA study:

- Proprietary data from manufacturers and suppliers.

- Review: reviewed by an independent, qualified third party according to the NMD Review Protocol.

- Publicity: product map public, environmental information limited access.

Category 2 LCA study:

- Proprietary data (unbranded) from groups of manufacturers and/or suppliers and industries.

- Review: reviewed by an independent, qualified third party according to the Review Protocol, indicating representativeness

- Publicity: product map public, environmental information limited access.

Category 3 LCA study:

- Proprietary data (unbranded) from National Environmental Database Foundation.

- Review: not reviewed according to the Review Protocol.

- Publicity: product maps and base profiles public.

For every customer who chooses the innovative traffic signs of Climate Signs, we place a traffic sign recycling collection bin free of charge. The bin is placed by an electric vehicle which is charged daily by our own solar panels. The moment the bin is full we will empty itCO2-neutrally. The old traffic signs are then kept in storage at Climate Signs until there is sufficient residual material for the subsequent recycling program. If there is sufficient return flow, the high-quality raw materials will be transportedCO2-neutrally to our circular chain partner ‘The Circular Plastics Factory’. At CPF, the technically depreciated traffic signs areCO2-neutral mechanically processed into injection moldable granules (re-granulate) and 100% processed into new traffic signs. Together with Circular Plastics Factory, we connect the circular chains.

From physical recycling, granulation to a fully circular end product, through injection molding.

During the product development phase, we at Climate Signs looked at a design for recycling andcarbon-neutral logistics.

This is the best part of our sustainable product concept: a product leaves the factory and returns at some point to be reprocessed again. Climate Signs and The Circular Plastics Factory want to convert as many residual materials as possible into high-quality applications, using the original material as much as possible.

Because plastic waste separation is very efficiently organized in the Netherlands and all our products are provided with a raw material QR code or plastic recycle code, our plastic traffic signs are easily separated by plastic type in the regular residual stream (residual waste) and 100% reused within another production process

With the introduction of the Climate Signs quality standard CS©, road authorities can make a well-considered choice for sustainability and the circular reuse of technically obsolete outdoor traffic signs. With the CS return system we extend the life cycle of existing raw materials and reduceCO2 emissions within existing production and distribution chains.

Climate Signs stands for sustainable product development, achieving aCO2-neutral society and introducing socially relevant innovation in relation to the continuously changing outdoor space.

Objectives:

- Reuse residues within existing chains efficiently and at a high value

- Replacing fossil, critical and unsustainably produced raw materials (aluminum) with biobased and recycled raw materials

- Products are designed circularly.

Pursuing a circular manufacturing process with value retention for all of our plastic residuals.

Principles:

- The realization of a clean residual stream (own waste separation by commodity family)

- Focus on value retention of the resource

- Focus on the circular use of re-granulate in the production of new road signs.

Conservation of raw material value is an essential component in our circular process. We believe that A-grade residual material should be reused as A-grade granulate to avoid ‘down grading’ of the material. As a result, we strive for customized solutions within our plastic recycling program.

We produce our traffic signs using an injection molding process. Each size of traffic sign has its own mold, so there is no waste during the production phase. This is in contrast to all other (innovative) traffic signs that are produced from traditional sheet material (aluminum, Bamboo, Rijsvlies, UPVC, Hemp, etc.).

Climate Signs has been certified at level 5 of theCO2 performance ladder, the highest level, since Q1-2023.

Climate Signs aims to consume 40% less fuel and natural gas by 2023.

The measures Climate Signs is taking and has taken to achieve these goals:

Electrifying commercial vehicles

Business premises is 100% equipped with Led lighting

Roof premises Q1-2023 equipped with 130 solar panels, generating electricity supply (premises and vehicles) by its own capacity. Climate Signs thus has energy-neutral housing and operations.

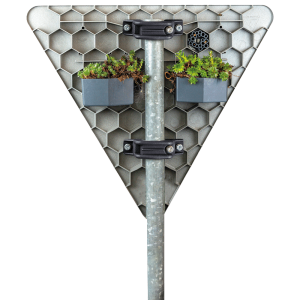

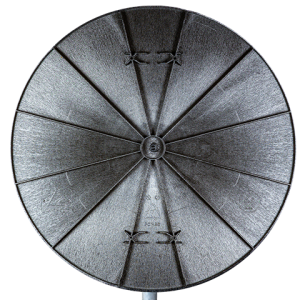

Climate Signs’ traffic signs feature a (honeycomb) rib structure on the back. The ribs are designed in such a way that they are too far apart, and too shallow to insert large popping fireworks between them. The road signs do not have a double-turned edge like aluminum road signs. This is the part where 95% of fireworks damage occurs on aluminum road signs. The distance between the sign and the pole is also too small to clip fireworks between. Since the launch of our innovative traffic signs, we have not received any fireworks damage reports from our customers

Our ambition is to recycle 45,000 kg of plastic waste into our products by 2023. We do this by recycling regional Dutch plastic for outdoor products. Our products are made from 100% recycled raw materials. The material is of high quality and very suitable as an alternative to aluminum traffic signs.

Use & Assembly

When designing the Climate Signs traffic signs we have taken into account (re)use of already existing fasteners. Each Climate Signs traffic sign is attached with a traditional hinge or mast brackets pitch 120 mm. The brackets are attached to the signs with special plastic screws M8

Price & Delivery Times

The price of a Climate Signs traffic sign is the same as the price of an aluminum US-20 traffic sign. For more information on the cost of CS traffic signs, contact your contact at Climate Signs

To achieve an easily scalable production process, we chose plastic injection molding. Injection molding is one of the most widely used forming techniques for plastic products. In this technique, a quantity of heated and thus liquefied plastic is injected under high pressure into a mold. This process is ideally suited to produce fast, and shape-retaining volume. Due to the short supply chain, we have fully customized production.

Product & Process

Traditional road signs are produced from coated or wet-painted aluminum sheet material. The primary production of aluminum is an energy-intensive process. Primary aluminum production uses 3.5% of global energy consumption. For the extraction of Bauxieterts, 30 km2(area municipality of Baarn, Culemborg, Haarlem, Tiel, Veldhoven, Vlissingen, Vught, Wageningen) of new earth surface is used annually. Most of this surface consists of forest areas. At the end of its life cycle, the vast majority of aluminum is recycled. The recycling process of aluminum is again an energy intensive process. To avoid quality degradation, 15-20% new aluminum is always added to the recycled aluminum material.

GlobalCO2 emissions have major consequences for people and the environment. To preserve a livable planet, we will have to reduce these emissions substantially in the short term. The Netherlands has made agreements with the European Union to reduce total emissions. The Netherlands set itself the goal of a 55%CO2 reduction in 2030 compared to 1990. For industry, this means a reduction of 19.4 megatons ofCO2 emissions by 2030.

GWP (Global Warming Potential):

An aluminum road sign emits 56.10 kg-CO2 eq. (source; project 085.0007 Category 3 study LCAs Road Furniture RVV Signs NIBE Research BV-2020).

A PCR-Sign traffic sign from Climate Signs emits 17.70 kg-CO2 eq. (source; project EPD-NIBE-20220711-28746 Category 1 study LCAs Road Furniture RVV Signs NIBE Research BV-2022).A mature tree absorbs about 22 kgCO2 per year. A single aluminum traffic sign emits about 2.55 x theCO2 annual uptake of a mature tree, while a PCR traffic sign emits 0.8 x theCO2 uptake. Looking at theCO2 emission figures and actual environmental impacts (landscape, water consumption), there is only 1 conclusion possible. We need to make a transition from traditional aluminum to recycled plastic in the coming years

The quality of honeycomb traffic signs has been extensively tested for hardness (dimensional stability) and bending resistance to horizontal and vertical point loads. The honeycomb ribbing on the back of the traffic sign ensures optimum strength and efficient use of resources. The sign is supplied according to the VNVF Ultimate Signing 20-year standard. This provides the signs with a printed image area on a class 3 retro-reflective film, coated with a protective laminate. Climate Signs’ traffic signs are the only alternative traffic sign where the carrier is fully CE certified. CE marking is a declaration by the manufacturer that the product complies with all applicable laws and regulations of the specific European EN 12899-1:2007 (NEN 3381:2020) guidelines. The traffic signs produced by Climate Signs are fully compliant with the applicable European laws and regulations for construction products, externally tested and validated, registered under the Certificate of Constancy of Performance No. 1388-CPR-5.2/2022

With Climate Signs’ traffic signs, we have connected the Dutch value chains (production and recycling of raw materials). Climate Signs’ traffic signs are produced entirely by the Dutch manufacturing industry. Because we have located the production process 100% in the Netherlands, we do not experience delays due to transport times or large price increases due to sea transport. We can therefore deliver our products faster and more reliably. Not only the production but also the high-quality development and innovation of our products takes place entirely on Dutch soil. Climate Signs focuses in the realization of its innovations primarily on employment within its own national borders. Made in Holland gets a valuable meaning again at Climate Signs.

Our 100% recycled aluminium traffic signs are produced by our partner CIRQ in Goes.

Climate Signs traffic signs are produced from a 100% biobased (sugarcane granulate), or 100% recycled Dutch PCR granulate (Post Consumer Recycled) raw material. Circularly used plastic is not only cost-effective but also a waste-reducing process. In addition, processing the recycled plastic requires less water consumption and significantly less energy. The PCR-Sign traffic sign offers the best possible quality available at the lowest possible climate impact. Together with our customers, we are making the journey to a zero waste society.

Material origin: (Netherlands)

- Public space: traffic mirrors, fixtures public lighting

- Automotive: dashboard parts, grills, interior and exterior parts

- Medical: enclosures for (electronic) medical equipment

- Telecommunications: cell phones

- Electronics: enclosures for electronic equipment and electricity meters, switch, wall outlets, plugs

- Office equipment: enclosures for computers, monitors, copiers and printers

- Household appliances: housings for microwave ovens and components for washing machines and dryers

Together with our supply chain partners, we reduceCO2 emissions during the production and distribution phase to 0 kgCO2. The circular raw materials used for our traffic signs are 100% recycled (waste). Climate Signs stands for aCO2 neutraland sustainable product development within an energy neutral environment, with the aim of securing a healthy living environment for current and future generations.

The energy required for production is 100% renewable, generated by its own solar panels.

Plastic has demonstrable added value for society (see TNO publication “Don’t waste it!” from 2020). Less weight results in fuel savings in transport, packaging extends the shelf life of food. In textiles, the use of plastics reduces the water consumption otherwise required for cotton cultivation. Resistance to rot and rust reduces waste in construction. The downside is that microplastics are released during production, use, recycling and at the end of the life cycle of plastics. These are solid plastic particles, smaller than five millimeters, in a variety of shapes and sizes.

Here we distinguish between primary and secondary microplastics.

Primary microplastics are deliberately added to products such as cosmetics (toothpaste, scrubs, glitter), (industrial) detergents, seeds, paints and coatings because of their functionality. Through wear and tear (of clothing and tires). Litter on roadsides, beaches and oceans can fragment into microplastics under the influence of sunlight (UV), friction, temperature fluctuation and microorganisms. Car tires (35%) and packaging (25%) are the largest source of microplastics. The remaining 40% is miscellaneous (textiles, other plastic products)

- Climate Signs’ traffic signs are not produced from primary microplastics (Rubber, PVC, PS, PP, PET, LDPE, EPS, POM, Nylon6, Nylon66, HIPS, PMMA). The material we use is not named in the TNO model Material Flow Analysis model (MFA) that systematically describes exposure to microplastics. The TNO model provides concrete tools for evaluating the effectiveness of current and future measures.

No plasticizers, flame retardants or other fillers are added to Climate Signs traffic signs. The only addition is a bio-based dye and Uv stabilizer. In the case of the color black or dark gray, no dye is even added at all. The Uv stabilizer ensures that our products do not discolor and therefore do not degrade due to Uv radiation.

The EU has developed 17 mitigation strategies. These strategies lead to a maximum reduction of 70% microplastics by 2050. In the “EU Strategy for Plastics in the Circular Economy” but also in popular and scientific literature, several mitigations have been proposed (expressed in MS1 to MS17).

- MS1 Prohibition of intentional microplastics; Climate Signs uses only high-quality raw materials.

- MS2 Restriction on Single-Use Plastics; Climate Signs uses only high-quality raw materials that are recycled within the primary chain.

- MS3 Upgrade water treatment system; n/a.

- MS4 Broader rollout of deposit money; Climate Signs will give a deposit for every returned traffic sign delivered.

- MS5 Clean up litter in roadside, park, forest; n/a.

- MS6 Ocean clean-up; n/a.

- MS7 Extraction plastic from landfills; because we work with high quality mono-flow raw materials, the old traffic signs will be sorted within the recycling chain and reused at high quality. To further support and simplify the recycling process, we have applied a raw material QR code and recycling code on the back of the traffic signs.

- MS8 Materials / grades with better MPI; n.a. we use high quality recycling streams as raw material.

- MS9 Better packaging concepts; n/a.

- MS10 Improved car tire (less wear); n/a.

- MS11 Precision recycling technology; we use a proprietary return system (see answer question 13).

- MS12 Implementation filter washing machine; n/a.

- MS13 Application enhanced air filter; n/a.

- MS14 Agricultural film recovery; n/a.

- MS15 Rubber collection along road and sports field; n/a.

- MS16 Car tire capture system; n/a.

- MS17 R strategies refuse & reduce;

During the design phase of the honeycomb traffic signs, we made optimal use of shaping, and basic structural strength. As a result, we have reduced the possible release of microplastics during use to an absolute minimum (process design for recycling). Despite the fact that the raw materials we use do not degrade in the environment, it is important to dispose of the loose parts in case of breakage. A road sign from Climate Signs is likely to break in a head-on collision. However, the fracture fragments will never be smaller than 5 mm. The signs are so tough and impact-resistant that when they break, larger pieces of plastic rather than microplastics are released.

Studies on the release of various Volatile Organic Compounds (oxygenated VOCs, chlorinated VOCs, alkanes, alkenes, mono-aromatics, acrylonitrile) during processing of recycled ABS, PS, PE, PP, PVC, PA and PC in a factory showed reassuring results. It was concluded that no health hazards occur during processing of PP and PE materials. For recycled plastics, the presence of different types of phthalates was measured. As far as measurable, the determined values according to REACH XVII were well above the threshold values. In the above study, DSC and FTIR tests were performed to identify organic traces in Q-UV treated material. However, no harmful traces were found.

Conclusion:

Based on what is currently known, the environmental impact of polyolefin waste products is reduced when they are recycled.

Hardly any harmful trace amounts can be measured, and where they are, they are well below regulatory thresholds.

The release of these traces into the environment is further reduced by an increase in the ratio of surface area to volume in recycled products, as is the case for the release of microparticles in thick-walled products.

Our products last at least 20 years and can be recycled again up to 9 times.

Should our product no longer be used, we will gladly take it back and together see what new life it can be given.

Requirements & Standards

Climate Signs’ traffic signs are the only alternative traffic sign where the loose carrier is fully CE certified. CE marking is a declaration by the manufacturer that the product complies with all applicable laws and regulations of the specific European EN 12899-1:2007 (NEN 3381:2020) standard. The traffic signs produced by Climate Signs are fully compliant with the applicable European laws and regulations for construction products, externally tested and validated, registered under the Certificate of Constancy of Performance No. 1388-CPR-5.2/2022

Climate Signs is ISO 9001 certified.

This certificate demonstrates that the organization meets the requirements and wishes of customers and stakeholders, that it applies the applicable laws and regulations, that it takes opportunities and risks into account and that continuous improvement is guaranteed within the organization.

ISO 14001

Climate Signs is ISO 14001 certified. This certificate demonstrates that the organization has an environmental management system that meets the requirements of the standard;

Want to know more about Climate Signs?

Please feel free to contact us!

Visiting address

Bramenberg 22

3755 BZ Eemnes

Contact details

Tel: 035-3038430

E-mail: info@climatesigns.nl

"*" indicates required fields