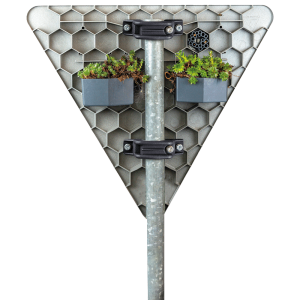

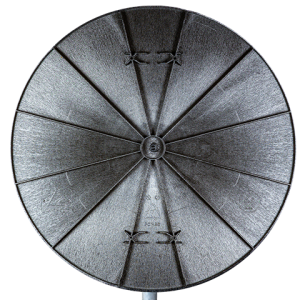

I am made in the Netherlands from a high-quality

ABS (Acrylonitrile-Butadiene-Styrene) regenerate.

Traceability of recycled plastics within the value chain:

For a truly circular economy, the raw material and production chain must evolve into a verifiable and reliable origin and return chain. This can only be achieved through an independent certification and validation process.

Increasing regulatory requirements from industry and government agencies demand harmonized and verifiable processing processes that traceably process recycled raw materials into new, high-quality applications. This is why Climate Signs has partnered with Kunststof Recycling Nederland. KRN has implemented the recycling process is in line with the EN 15343:2007 standard, and has the required procedures to ensure the traceability of the recycled raw materials.

To ensure that raw materials used by Climate Signs are recycled, the origin must be traceable and verifiable throughout the value chain. At KRN, the origin of pre- and post-consumer materials is verified in product claims and independently certified (Chain of Custody principle).

Benefits traceability and transparency raw materials:

- Facilitates traceability of recycled materials throughout the value chain

- Promotes transparent use of recycled plastic in new products

- Reinforces reliable and verifiable claims about recycled plastic

- Increase customer confidence

Together with our manufacturing partner Euronyl – DPI, we injection mold Climate Signs’ traffic signs climate-neutral.

Because Climate Signs exclusively uses high-quality raw materials, the traffic signs are 100% recyclable within the value chain (Cradle to Cradle) after the end of their technical or economic life span. The raw material for Climate Signs’ traffic signs thus remain in the economic cycle as long as possible so that everything is reused.

The Netherlands is building a circular economy in 2050. Why wait until 2050 when you can use Climate Signs to buy fully circular as early as 2024!

What is ABS regenerate?

ABS regenerate, in full Acrylonitrile butadiene styrene, is a thermoplastic that combines the strength and rigidity of acrylonitrile and styrene polymer with the robustness of polybutadiene rubber. The result is a plastic distinguished by its durability, impact resistance, and excellent surface finish. The ABS regenerate used by Climate Signs is made from a 100% recycled raw material. The raw material is processed into an injection moldable new regenerate pellet within the recycling process.

How is ABS recycled?

When our chain partner KRN receives the mixed plastic streams, the mono and mixed plastic streams are separated. Using the latest recycling technology, KRN is able to separate plastics by density, color, structure and shape. As a result, they are able to separate 7 different colors for each type of plastic. At the recycling plant, the ABSS is selected for our desired color, cleaned and shredded, leaving a pure mono-flow ABS plastic. Since ABS is a high quality plastic raw material, the Climate Signs traffic sign will be processed within the existing plastic recycling chains into new high quality grinding material.

How and where is ABS used?

Because ABS is a highly resilient and impact-resistant plastic, it is used for:

- Electronic enclosures (sockets, tools);

- Computer keyboards;

- Toys, such as Lego blocks;

- Housing of power tools;

- Outlets;

- Computer components;

- Auto parts;

- Luggage cases;

- Aircraft applications;

- Helmets;

- Chairs, tables, containers, etc.

What are the properties of ABS?

Advantages use recycle ABS regenerate raw material:

Is ABS a toxic material?

No, ABS is not a toxic material. It is used in many children’s toys and household appliances, contains no harmful substances.

Certification raw material:

To reduce the high demand for new raw materials, it is very important to strengthen the circular economy on an ongoing basis. Here, energy waste in production is as important as reducing waste at the source.

Because Climate Signs processes 100% circular raw materials in acarbon-neutral production process, the Netherlands Circular 2050 goals have already been achieved with us.

To ensure the quality and circularity of the products supplied, all raw materials are purchased and processed under a recycling certificate. The quality and origin is therefore always traceable.

The certification gives customers confidence that the recyclate material has been recycled in the best possible way, with respect for the environment and in compliance with national regulations. The certification also demonstrates that the output produced complies with relevant environmental legal regulations.

Production:

Climate Signs’ traffic signs are produced 100% in the Netherlands with green electricity.